We use laundry equipment everyday with out a lot of thought to the potential hazards they may pose. According the the Consumer Product Safety Commission washers and dryers are responsible for more then $230,000,000 worth of property damage a year in the US alone. Most of the common problems at the root of these statistics are easy to address.

Power Cords

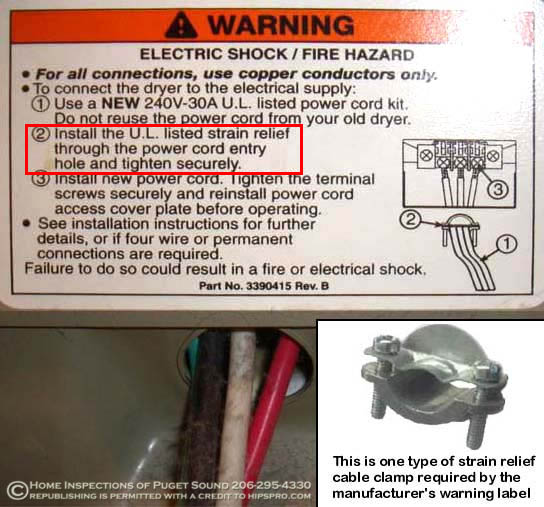

We found this dryer power cord on an inspection, notice it does not have a proper strain relief connector.

|

| Dryers use a lot of power, and usually do not come with their power cords installed when you buy them. When hooking up a power cord, follow the manufacturers instructions, and be sure to have the proper strain relief fitting. Since dryers vibrate and can have sharp edges to the sheet metal enclosures, cords can short out, causing a potential fire or electrocution hazard. Washing machine hoses Dryer vents and lint build up It is recommended that you check and clean the dryer venting regularly. Use flexible metal pipe, not the foil or vinyl accordion type hoses, they are more likely to catch lint and have an increased risk of fire. Smoke detectors are important in laundry areas, since fires associated with dryers cause more then $80 million of damage a year. Be sure that dryers are properly vented outside and not leaking inside the home, attic or crawlspace as this moisture is a conducive condition for structural pests. If there is significant lint buildup inside, your dryer vent is likely leaking.

Fresh air/back drafting

Explosion hazards |

If you find this information useful, don't keep us a secret! List us on any of your favorite networking / bookmarking sites

This hot water heater has exhaust rollout. Improper flue design or inadequate air supply can cause combustion gasses to vent into the home. If your heater has these stains please have it checked out.

This hot water heater has exhaust rollout. Improper flue design or inadequate air supply can cause combustion gasses to vent into the home. If your heater has these stains please have it checked out. GFCIs

GFCIs